|

This is fairly simple to do

yourself, to start off, you need some Plexi-glass. This can be found at

a glass shop, Home Depot, or Lowes. My case was made out of 3/8 Plexi-glass,

Ό can be used but you may need to re-measure. The glass can be cut to

size with a regular table saw.

Also, you will need some acrylic

glue and acrylic hardware (latches, hinges , and a door pull). You may

be able to find these locally or you can get them from

AllAcrylic.com which is where I did. Prices are reasonable and if

you spend $30 you get free shipping.

Here is what hardware you need:

|

1 pair of hinges 1-1/2 x 1-3/4 |

|

| |

|

|

1 Acrylic pull (Small) |

|

| |

|

|

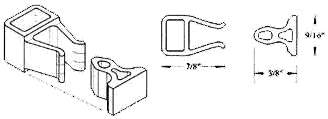

1 door catch |

|

They also sell the glue and an

applicator ( I used a small syringe).

Next, you need some 80 grit,

and 240 grit sandpaper ( or something close) which can be found at

Wal-Mart. The 80 grit is used for the glue joints and the 240 is used

for smoothing the edges.

Tools needed: Table saw, Jointer, Electric sander,

Clamps, and a Propane torch.

1) Cut the Plexi-glass : 2 pcs

21 x 11 ( Front & Back)

2 pcs 10 Ό x 3 ( Sides)

2 pcs 21 x 3 ( Top &

Bottom)

Note: These dimensions are

FINISHED dimensions. I recommend you add Ό to each measurement so you

can dress the edges.

2) The table saw

will leave a very rough edge. If you have access to a Jointer, you can

smooth the edges somewhat with it.

Make sure the depth is set for

no more than 1/16 or it will chip the glass. Run all of the edges

through once then measure for the final size. If it is still not the

right size, continue to run the edges through until it is the right

size.

3) Using the sander with 80 grit

paper, sand the edges so they are visibly smooth.

Using the sander with 240 grit

paper, sand the edges that will be seen ( All 4 edges on the front &

back, and 1 edge on each of the sides, top & bottom). Sand these as best

as you can they will be flame polished to look like finished glass.

FLAME POLISHING:

Flame polishing is ,

economical method of edge polishing that is preferred by some

fabricators. Do not use this method on edges that will be glued or

crazing will result (The fine cracks to the

left)

The flame should be bluish,

nearly visible, approx. 4 long, and narrow. Hold the torch so that the

tip of the flame touches the edge of the acrylic sheet. Move the torch

along the edge at a speed of approx. 3- 4 per second.

Overheating and bubbling may

occur if the flame is moved too slowly. If the first pass does not

produce a completely polished edge, allow the piece to cool; a second

pass will often improve the surface finish.

4) After all the edges are done,

wash the glass with soap & water. DO NOT use

a cleaner such as Windex The ammonia in it will cause the glass to

turn yellowish over time.

5) Dry fit the bottom,

sides, top, and bottom. Check to see if the wood display will fit inside

still. It should be a tight fit. If it seems to be too tight on the top

and bottom, dont give up just yet. It will fit.

6) Glue the sides together. Be

careful the glue is liquid and a little bit goes a long way. That is why

I used a syringe, put a fine bead along one edge and butt together. The

glue sets pretty quickly. If you have a frame clamp, you can glue them

all together. If not, glue one joint at a time. You can use anything on

the inside to square it up. Use masking tape to hold the joint until it

is set.

7) Glue the back on next.

8) If you plan on mounting the

case to the wall, drill holes through the back.

9) Lay the lid on top and tape

it in place. Place the tape where its not in the way of your hinges and

door pull. Glue hinges and door pull ( Allow

the hinges to dry COMPLETLEY or they will break ).

| 10)

Glue the female end of the catch to the inside of the case The opening for the male end should be side

ways not up and down. This way when the door is shut, the catch

keeps it from sagging. |

|

| |

|

|

11) Snap the male end

into the glued catch, put a little glue on it and close the door. Tape

the door in this position until it is COMPLETLEY dry. |

|

12) The case is complete!!

Check for fit. I made mine snug so it wouldnt come out. What I did was

put the wooden case in the freezer for a few hours and I let the case

set in the sun. Freezing the wooden case made it shrink, the sun

expanded the case. Take the case and mount it, then slide the wooden one

in. Once the temp was equal, I had a snug fit.

Any questions, comments?

Contact me at

MarkU88@ntelos.net

Return to

Collectors Helping Collectors

|