|

From Concept to

Contract

Not known to many, the “Super Pumper”

concept dates back to 1910 when Mr. William Francis Gibbs an

internationally renowned naval architect came up with an idea for

the “land fireboat”, but his ideas where not received with serious

consideration. In the 1930’s Gibbs had plans drawn up for his “land

fireboat” using two Zeppelin engines, but this was still just a

concept, while he was designing the fireboat FIREFIGHTER for New

York City. He could not get the land fireboat out of his head;

penning down designs and also showing practical reasons for his

idea: which included the land fireboat acting as a portable pumping

station delivering water from lakes ponds and other inland mass

water sources. Giving greater water pressures than existing fire

fighting equipment at the time, unfortunately for Gibbs such a

vehicle was still no more than just a dream. Not being possible, due

to engineering limitations that would restrict such a vehicle until

the 1960’s. Diesel engines that could fulfill this type of pumping

requirement and be light enough to mount on a truck did not exist,

as well as hose that could cope with the pressures in Gibbs’ design.

Mr. William Francis Gibbs went on to be come America’s foremost ship

designer going on to design 74% of the U.S. Navy’s fleet used during

World War II plus the passenger liner S.S. UNITED STATES. Gibbs

never gave up on his land fireboat, he became encouraged by newly

developed lightweight diesel engines for the British navy as well as

the U.S. Navy’s development of high pressure hoses that could

withstand the requirement of the envisaged fire fighting apparatus.

During 1962, Gibbs invited Mack Trucks to take part in the design of

what is known today as the SUPER PUMPER and its companion Tender;

with studies by Gibbs and Mack engineers into engineering

feasibility, design right through to construction and materials. The

DeLaval Turbine Inc was commissioned to design a multi-stage

centrifugal pump with a Naper-Deltic T18-37C diesel to power the

pumps; Gibbs and Cox Inc would provide the necessary services to act

as design agents leaving Mack Trucks acting as the general

contractor. Teams of managers, scientists and engineers from both

corporations were assembled to work on this project.

20th April 1963 F.D.N.Y. experienced its busiest day to date, the

combination of several dry spells plus prolonged water shortages led

to one of the biggest fires on Staten Island. Staten Island was

mainly thick brush, oak and pine trees with a small clusters of

homes. On that day a series of small brush fires quickly committed

all Staten Island’s fire companies; there was almost no water

available due to the drought and poor water mains, additional fire

companies were dispatched from Brooklyn and Manhattan. Their

response time was hampered by the need for the additional companies

to be shipped across to Staten Island by ferry boats. As a result of

the delay in providing adequate fire cover, the total loss on the

Island exceeded

$2 Million with over 1300 firefighter and over 80 Fire companies

being committed, firefighter could do little to save property and

land due to the lack of water. Firefighters in the rest of the city

were kept busy in that twenty four hour period with over 2000 alarms

being transmitted for fires.

Gibbs watched the events of that day; after he analyzed all the

statistics he came to the conclusion that his land fireboat could

have had great effect on the outcome of the Staten Island fire. It

could have pumped water from the Tottenville water front providing

an unlimited supply of water to the working companies. This was it;

the time had come for his idea to become a necessity in a modern day

fire service. He approached the F.D.N.Y. The department’s officials

were enthusiastic about the idea of a large high pressure pumping

appliance. But one problem! The department’s funding for the next

financial year had been budgeted; this was a set back for Gibbs, but

he was determined to sell this idea to the City. After attending

several hearings and testifying to justify the expense, the approval

was eventually given and at 10:00am December 3rd 1963 Fire

Commissioner Edward Thompson signed the contract for Mack Trucks to

build the Super Pumper and it’s Tender at a cost of $875,000.00 to

the city. Commissioner Edward stated, “This will be the most

powerful firefighting equipment the world has ever known.”

The Super

Pumper

The tractor utilized for

the Super Pumper was a commercial Mack, model designated F715FSTP.

The engine was a four stroke cycle Mack END864 V8 diesel of 255 HP.

An Allison CLT4460 six speed semi-automatic transmission was coupled

to the engine and equipped for a power take off unit to drive the

priming pump and starting air compressor for the pump engine.

Additional power take off units powered the air brake compressor

including the power steering pump. The semi-trailer was mounted to the fifth wheel of the tractor. Mounted at the rear of the tractor

trailer is a DeLaval six stage pump having a built in piston type

valve to allow for operation in either pressure or volume positions.

To supply water to the pump there are four unchecked inlets to the

rear. Two of these are 4 1/2 inch while the other two are 12 inch

with 4 1/2 inch inlets set into their caps. There are also two 4 1/2

inch checked inlets on each side of the apparatus at the rear. There

are a total of eight 4 1/2 inch discharge outlets with four located

on each side of the apparatus. Directly coupled to the pump is the

Napier-Deltic engine this is an 18 cylinder turbo-blown compression

ignition, water cooled opposed piston type operating on a two stroke

cycle. The exhaust silencer is intended to reduce the overall engine

noise level within 6ft distance from the apparatus. On each side of

this silencer are 200 gallon diesel fuel tanks which can feed the

diesel independently or simultaneously. The pump engine is started

by air pressure (450PSI) provided from air tanks located on the

tractor. There is a single master shut off to prevent engine over

speeding. A mechanical crane is located at the rear to assist in

positioning and supporting the rigid 12 inch suction connections. By

the end of 1964, the pumping unit of the Super Pumper was

approximately 90% complete.

the fifth wheel of the tractor. Mounted at the rear of the tractor

trailer is a DeLaval six stage pump having a built in piston type

valve to allow for operation in either pressure or volume positions.

To supply water to the pump there are four unchecked inlets to the

rear. Two of these are 4 1/2 inch while the other two are 12 inch

with 4 1/2 inch inlets set into their caps. There are also two 4 1/2

inch checked inlets on each side of the apparatus at the rear. There

are a total of eight 4 1/2 inch discharge outlets with four located

on each side of the apparatus. Directly coupled to the pump is the

Napier-Deltic engine this is an 18 cylinder turbo-blown compression

ignition, water cooled opposed piston type operating on a two stroke

cycle. The exhaust silencer is intended to reduce the overall engine

noise level within 6ft distance from the apparatus. On each side of

this silencer are 200 gallon diesel fuel tanks which can feed the

diesel independently or simultaneously. The pump engine is started

by air pressure (450PSI) provided from air tanks located on the

tractor. There is a single master shut off to prevent engine over

speeding. A mechanical crane is located at the rear to assist in

positioning and supporting the rigid 12 inch suction connections. By

the end of 1964, the pumping unit of the Super Pumper was

approximately 90% complete.

| Length |

43'3" |

|

| Width |

8' |

| Height |

11' 4" |

|

Weight |

68,500

pounds |

|

Maximum speed |

42 MPH |

|

Rated horsepower of pump engine |

2400 |

|

Fuel

carrying capacity |

400

gallons |

|

Pump |

6 stage 2 position |

|

Pump capacity |

8800 GPM at 350 PSI |

|

Serial number |

F715FSP1000 |

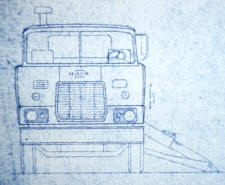

The Tender

The primary tender would be a flat hose

bed trailer instead of the hose reels indented in the original

design; unfortunately the intended design was not practical at the

time of manufacturing due to limited technology. When a working

model of the tender with reels was made, problems surfaced with the

hose butts on the reels that proved the design to be impractical. A

manifold system with gauged discharge outlets would also be included

in the trailers design. Utilizing the same basic Mack cab over

tractor as that of the Super Pumper, modifications were made to fit

an operating platform that would support the high pressure monitor,

designated model F715FSTT... When originally delivered, the Tender

had a large McEntyre monitor similar to those on the fireboats. This

was replaced with a large Stang "Intelligiant" monitor which had an

8 inch barrel operated by hand wheels including interchangeable tips

of 3, 3 1/2, 4, 5 inch and a 2000 GPM fog tip. The monitor was

supplied via the four 4 1/2 inch checked inlets with two located on

each side of the tractor. There were also hydraulically operated

outriggers on each side of the tractor located below the operating

platform attached to the frame. Their purpose is to stabilize the

rig and counteract the nozzle reaction of back pressure. These

outriggers were also equipped with mechanical interlocking devices

in the event of hydraulic failure. The maximum reach of a stream

thrown by the tender's monitor was 600 feet. The bulk of the trailer

consists of a divided hose bed with each compartment capable of

carrying 1000 feet of 4 1/2 inch hose. The front end of the trailer

was equipped with a large “walk in” type compartment. The rear axles

were steerable from a reverse seated position located at the rear

center of the trailer; this was to be removed in a later

modification. This apparatus was designed and manufactured so that

the tractor could easily uncouple from the trailer. This allowed for

the tractor, carrying the large monitor, to maneuver easily and into

tighter spots than wouldn’t be possible as a tractor trailer

combination.

| Length |

41'6" |

|

| Width |

8' |

| Height |

11' 4" |

|

Weight |

60,000 pounds |

|

Monitor capacity |

10,000 GPM |

|

Reaction force of monitor |

5000 PSI |

|

Maximum reach of stream |

600' |

|

Serial number |

F715FSTT1001 |

Satellites

The

Super Pumper System was developed out of necessity due to the

inability to build the tender as originally designed. The new

system consisted of the Super Pumper, Tender, and three

satellite tenders that were developed to carry the same amount

of hose and equipment as originally intended for the tender.

Each of the three satellite

t were

built on the Mack "C" model cab designated model C85FD.

They were equipped with Mack END673 176 HP diesel engines and

manual transmissions. Each was capable of carrying 2000 feet of

4 1/2 inch hose and had a Stang "Intelligiant" monitor that had

a 6 inch barrel which was manually controlled. These monitors

had a water delivery capability of 4000 GPM and had 2, 2 1/2, 3,

3 1/2, and 4 inch tips as well as 700 and 2000 GPM fog tips.

Each satellite had four inlets with two on each side. There was

one checked and one unchecked inlet on each side. When lines

were supplied to a satellite they were hooked up to the

unchecked inlets first.

All three

satellites were equipped with portable manifolds. These

manifolds had 4 1/2 inch inlets and either six 2 1/2 inch gated

outlets or two 3 inch and four 2 1/2 inch gated outlets.

Weighing a little over 200 pounds, the portable manifolds were

utilized efficiently at operations requiring many hand lines the

Super Pumper could supply the manifold from a remote location

with the manifold positioned in front of the fire scene. were

built on the Mack "C" model cab designated model C85FD.

They were equipped with Mack END673 176 HP diesel engines and

manual transmissions. Each was capable of carrying 2000 feet of

4 1/2 inch hose and had a Stang "Intelligiant" monitor that had

a 6 inch barrel which was manually controlled. These monitors

had a water delivery capability of 4000 GPM and had 2, 2 1/2, 3,

3 1/2, and 4 inch tips as well as 700 and 2000 GPM fog tips.

Each satellite had four inlets with two on each side. There was

one checked and one unchecked inlet on each side. When lines

were supplied to a satellite they were hooked up to the

unchecked inlets first.

All three

satellites were equipped with portable manifolds. These

manifolds had 4 1/2 inch inlets and either six 2 1/2 inch gated

outlets or two 3 inch and four 2 1/2 inch gated outlets.

Weighing a little over 200 pounds, the portable manifolds were

utilized efficiently at operations requiring many hand lines the

Super Pumper could supply the manifold from a remote location

with the manifold positioned in front of the fire scene.

SATELLITES

| Length |

25'7" |

|

| Width |

8' |

| Height |

10'9" |

|

Monitor

capacity |

4000 GPM

Butts |

|

Model designation |

C85FD |

|

RUNS AND WORKERS |

|

SUPER PUMPER

and

TENDER

The last response made

by the Super Pumper occurred on

April, 24th, 1982. |

YEAR |

RUNS |

WORKERS |

|

1965 |

46 |

7 |

|

1966 |

163 |

59 |

|

1967 |

114 |

41 |

|

1968 |

237 |

67 |

|

1969 |

219 |

56 |

|

1970 |

234 |

78 |

|

1971 |

206 |

66 |

|

1972 |

165 |

54 |

|

1973 |

190 |

81 |

|

1974 |

231 |

114 |

|

1975 |

216 |

134 |

|

1976 |

99 |

63 |

|

1977 |

41 |

28 |

|

1978 |

24 |

17 |

|

1979 |

38 |

26 |

|

1980 |

25 |

12 |

|

1981 |

26 |

11 |

|

1982 |

11 |

4 |

|

TOTAL |

2285 |

918 |

The above text is an adaptation of

John A. Calderone’s book entitled, The F.D.N.Y. Super Pumper

System. If you are looking for a more in-depth history of the

above F.D.N.Y. vehicles mentioned in this article, I strongly

recommend you purchasing a copy of the book which includes over

100 photos and illustrations. The book is still available from

the following sites:

http://www.fireapparatusjournal.com/sp-order.pdf and

www.westchestercollect.com. Also available are copies of the

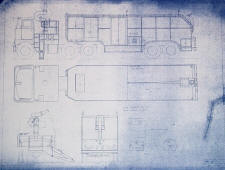

blue prints for the Super Pumper System from

http://www.grovegraphics.com/blueprints.htm

The blue-line blueprint will be made

from the original velum drawing by a California firefighter that

is over twenty-five years old. This print is NOT a photocopy but

an actual blueprint. The overall size of this blueprint is

approximately 20 1/2 x 15 1/2 inches.

Click Here for

Review

|

were

built on the Mack "C" model cab designated model C85FD.

They were equipped with Mack END673 176 HP diesel engines and

manual transmissions. Each was capable of carrying 2000 feet of

4 1/2 inch hose and had a Stang "Intelligiant" monitor that had

a 6 inch barrel which was manually controlled. These monitors

had a water delivery capability of 4000 GPM and had 2, 2 1/2, 3,

3 1/2, and 4 inch tips as well as 700 and 2000 GPM fog tips.

Each satellite had four inlets with two on each side. There was

one checked and one unchecked inlet on each side. When lines

were supplied to a satellite they were hooked up to the

unchecked inlets first.

were

built on the Mack "C" model cab designated model C85FD.

They were equipped with Mack END673 176 HP diesel engines and

manual transmissions. Each was capable of carrying 2000 feet of

4 1/2 inch hose and had a Stang "Intelligiant" monitor that had

a 6 inch barrel which was manually controlled. These monitors

had a water delivery capability of 4000 GPM and had 2, 2 1/2, 3,

3 1/2, and 4 inch tips as well as 700 and 2000 GPM fog tips.

Each satellite had four inlets with two on each side. There was

one checked and one unchecked inlet on each side. When lines

were supplied to a satellite they were hooked up to the

unchecked inlets first.